Sensational Tips About Do SMD LEDs Have Polarity

Led Diagram Polarity

Unraveling the Mystery

1. Navigating the World of Tiny Lights

So, you're tinkering with some snazzy surface-mount device (SMD) LEDs, huh? Awesome! But then that little voice pops into your head: "Wait a minute...do these things even have a positive and negative side?" It's a valid question, and one that can save you from a whole lot of head-scratching and maybe even a fried LED (nobody wants that!). The short answer? Yes, SMD LEDs definitely have polarity. It's not always obvious at first glance, but understanding this is key to getting your project lit up properly. Think of it like trying to put batteries in a remote control the wrong way — it just won't work, and might even cause damage!

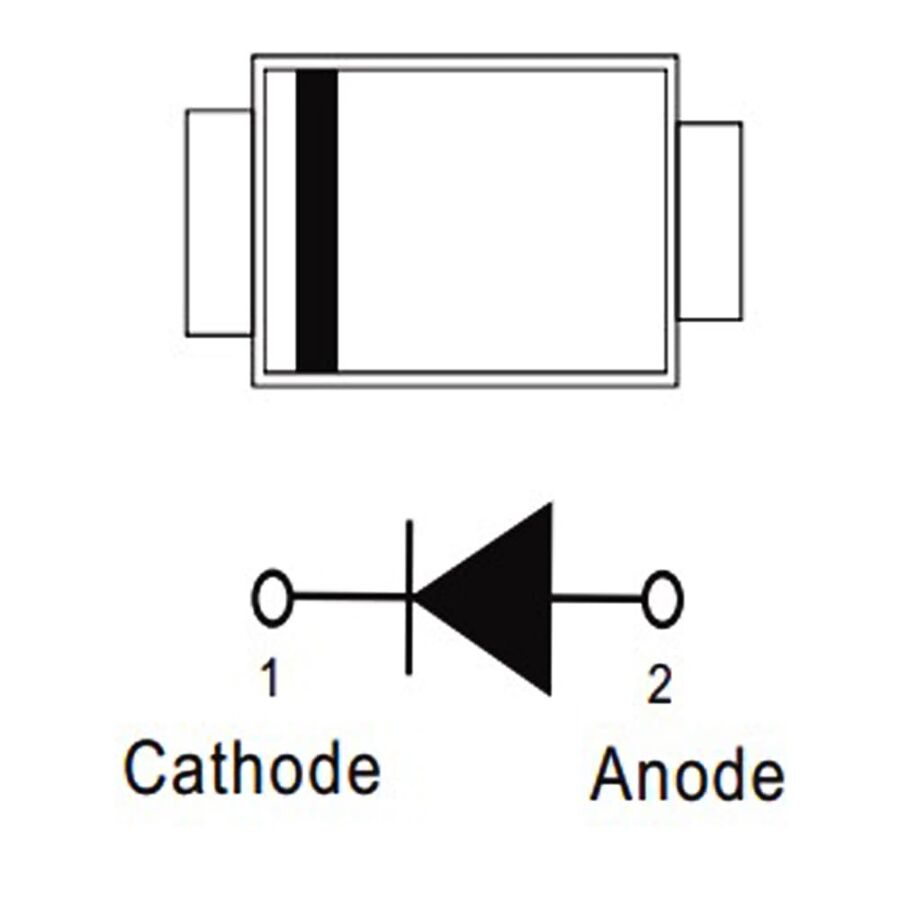

But why does polarity matter, anyway? Well, an LED (light-emitting diode) is a diode, and diodes are semiconductors. That basically means they only allow electricity to flow in one direction. If you hook up an SMD LED backwards, it won't light up. Worse yet, if you pump enough voltage through it in reverse, you could permanently damage the LED. Imagine trying to force water uphill — eventually, something's gotta give! So, let's dive into how to identify the polarity on these miniature marvels.

It's also important to note that different types of SMD LEDs can have slightly different markings to indicate polarity. This is where datasheet research becomes your best friend. Manufacturers usually provide detailed diagrams and specifications, so you can confidently connect your components. Don't be intimidated by datasheets — they're like a treasure map leading to successful illumination! Also, consider getting an LED tester. These simple devices can quickly verify the polarity and functionality of your LEDs, saving you time and potential headaches.

Think of it as needing to know which end of the key goes into the lock first, because it wouldn't be fun if you were to put it in backwards. Understanding LED polarity is one of the foundational steps in using LEDs to their full potential. After all, whether you're creating an art installation, repairing a circuit board, or simply adding some flair to your favorite gadget, doing things the right way helps with the end result of the project!

Decoding the Markings

2. Spotting the Signs on Your SMD LED

Okay, so how do you actually tell which side is positive (the anode) and which is negative (the cathode) on an SMD LED? This is where things can get a little tricky, as the markings can vary depending on the manufacturer and the type of LED. But fear not! There are a few common indicators to look for.

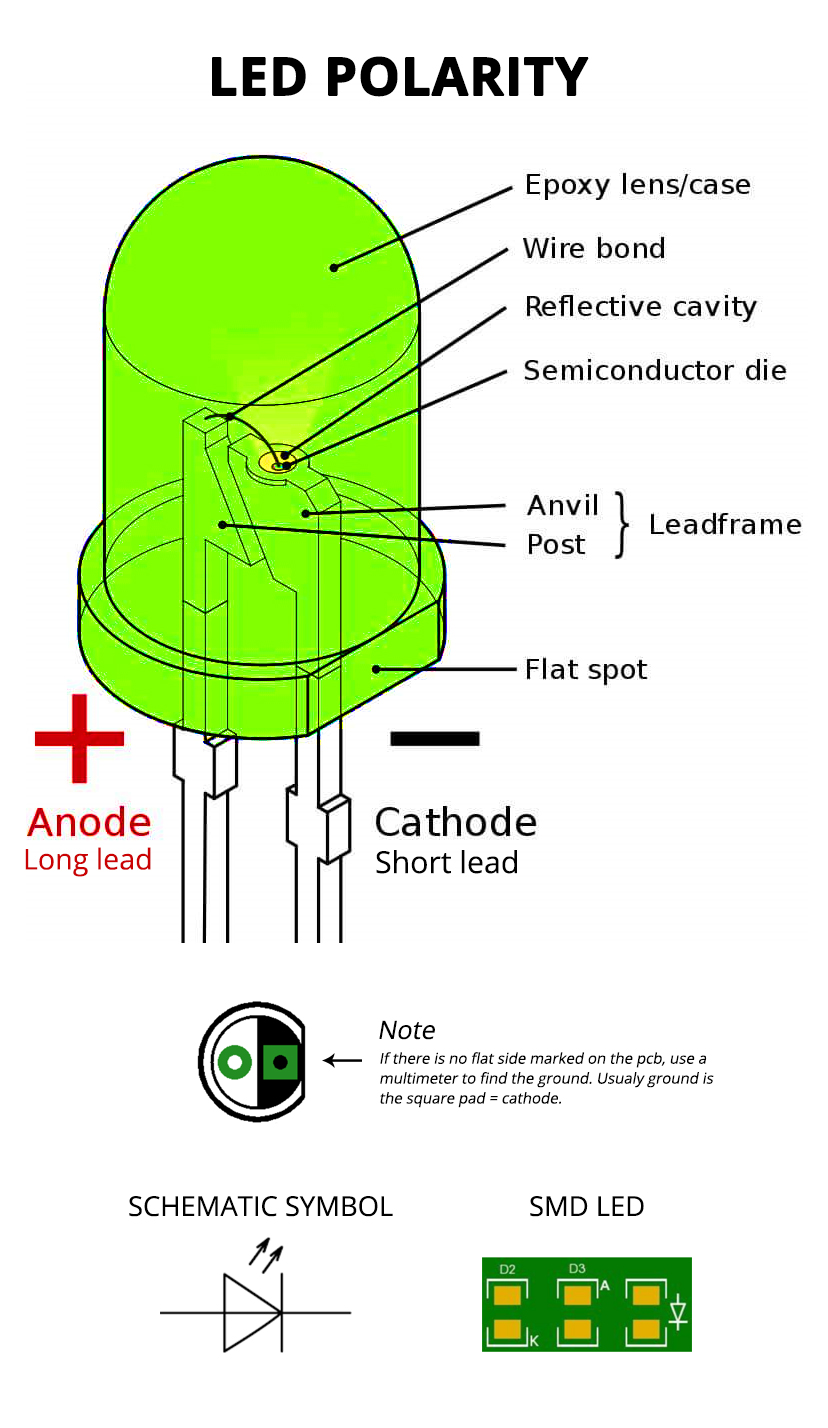

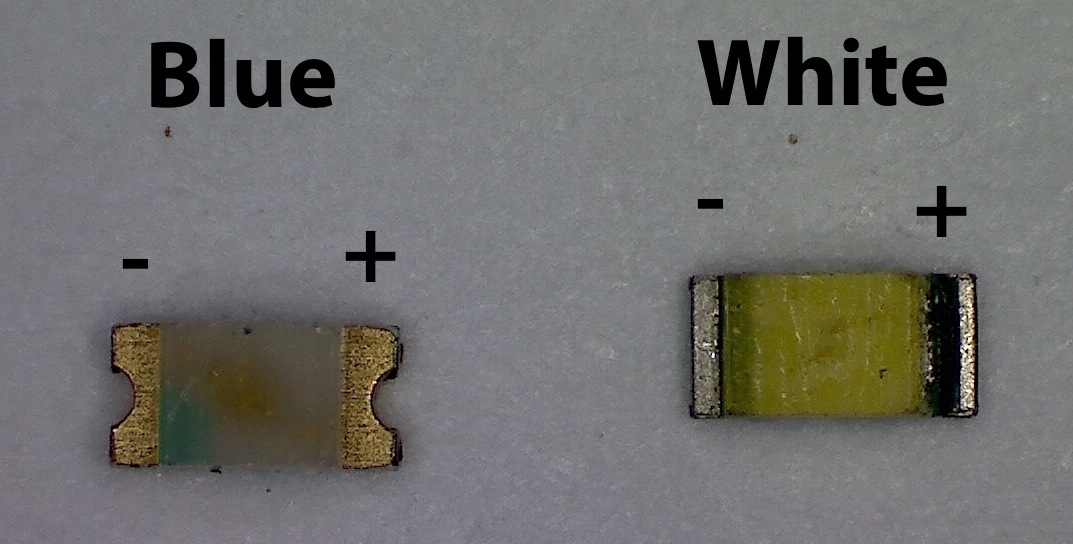

One of the most common clues is a small green mark on the LED package. This mark usually points to the cathode (negative) side of the LED. However, be aware that the color of this mark can differ between manufacturers, so this is just one clue to look for. Another useful visual aid is the shape of the plastic housing. Some SMD LEDs have a small bevel or a slightly different shape on the cathode side. If you can spot this subtle difference, it can help you confidently determine the polarity.

Beyond that, a little bit of detective work might be necessary. Use a multimeter. A multimeter set to diode test mode can help you identify the polarity of the LED. Connect the positive lead of the multimeter to one terminal of the LED and the negative lead to the other terminal. If the LED lights up (even dimly), you've connected it correctly — the positive lead is on the anode and the negative lead is on the cathode. If it doesn't light up, try reversing the leads. It's like trying to figure out if a light switch is on or off — sometimes you just need to flip it to see!

If you are still unsure after looking at the markings, you could search the SMD LED model number to find the datasheet. Datasheets usually provide detailed pinout diagrams indicating the anode and cathode. Don't feel discouraged if it's not immediately obvious! With a little practice, you'll become a pro at spotting the clues and connecting your SMD LEDs with confidence.

The Datasheet is Your Friend

3. Unlocking the Secrets of the SMD LED

We've mentioned datasheets a few times, so let's talk about why they're so crucial. A datasheet is essentially a technical document provided by the manufacturer that details all the specifications and characteristics of a particular component. Think of it as the instruction manual for your SMD LED — it tells you everything you need to know to use it correctly and safely.

The datasheet will usually include a drawing of the LED package, clearly indicating which pin is the anode and which is the cathode. It will also specify the forward voltage (the voltage required to light up the LED) and the maximum current that the LED can handle. Ignoring these values can lead to burnt-out LEDs and a lot of frustration. Reading the datasheet might seem tedious, but it can save you a lot of time and trouble in the long run. It's like reading the recipe before you start baking — you'll be much more likely to end up with a delicious cake (or, in this case, a properly functioning circuit).

Furthermore, datasheets will inform you of the current limit which is a crucial piece of information to consider if you want your LED lights to remain working for a long time. Also, the datasheet contains the operating temperatures which you should also be aware of. If the LED is for outside use and in hot climates, it's better to use another LED with a wider operating temperature range.

So, next time you're working with SMD LEDs, take a few minutes to find the datasheet. It might seem like an extra step, but it's an investment that will pay off in the form of fewer mistakes, longer-lasting LEDs, and a much smoother project overall. Trust me, your future self will thank you!

Avoiding Common Mistakes

4. Keeping the Magic Smoke Inside

Working with SMD LEDs can be fun and rewarding, but there are a few common mistakes that beginners often make. Knowing these pitfalls can help you avoid them and ensure a successful project. Let's shine a light on some of these common errors.

One of the biggest mistakes is applying too much current to the LED. LEDs are current-sensitive devices, and exceeding their maximum current rating will quickly lead to damage. Always use a current-limiting resistor in series with the LED to regulate the current flow. The value of the resistor will depend on the supply voltage and the forward voltage of the LED. There are plenty of online calculators that can help you determine the correct resistor value.

Another frequent mistake is soldering SMD LEDs incorrectly. These tiny components can be tricky to solder by hand, especially if you're not used to working with surface-mount devices. Use a fine-tipped soldering iron, and apply heat to the pad on the circuit board, not directly to the LED. Use solder paste to help the solder flow evenly. And don't forget to use flux! Flux helps clean the pads and promotes good solder adhesion.

Lastly, double-check the polarity before soldering the LED to the board! It is always better to check the connections for a second time before you proceed to solder. It takes 5 seconds to check but it could take 5 minutes to undo an accidental soldering job, especially with SMD LEDs.

Remember, patience is key! Don't rush the soldering process, and take your time to ensure that each connection is solid. With a little practice, you'll be soldering SMD LEDs like a pro in no time!

Frequently Asked Questions (FAQ)

5. Your Burning Questions Answered

Still got questions about SMD LED polarity? No problem! Here are some frequently asked questions to help clear things up.

6. Question 1

If you connect an SMD LED backwards, it simply won't light up. LEDs are diodes, and they only allow current to flow in one direction. However, if you apply too much voltage in reverse, you could damage the LED permanently. So, it's always best to double-check the polarity before powering up your circuit.

7. Question 2

Yes, you can use a regular (through-hole) LED in place of an SMD LED, but you'll need to make some adjustments to the circuit board. Through-hole LEDs have leads that are designed to be inserted into holes in the circuit board, while SMD LEDs are designed to be soldered directly to the surface of the board. You'll need to find a way to connect the leads of the through-hole LED to the SMD pads on the board. This can be done using wires or by creating a small adapter board. Just be sure to maintain the correct polarity!

8. Question 3

No, not at all! SMD LEDs come in a wide variety of sizes, shapes, colors, and brightness levels. They also have different voltage and current requirements. It's important to choose the right SMD LED for your specific application. Always refer to the datasheet to ensure that the LED meets your needs. Different sizes mean that you can't use a certain resistor for one SMD LED to the next. This means more datasheet reading and researching!

9. Question 4

To start working with SMD LEDs, you'll need a few essential tools, including a fine-tipped soldering iron, solder paste, flux, tweezers, and a magnifying glass (or a microscope, if you're feeling fancy!). A multimeter is also helpful for testing the polarity and functionality of the LEDs. If you plan to do a lot of SMD soldering, you might also consider investing in a hot air rework station, which can make it easier to remove and replace SMD components.