Beautiful Tips About How To Calculate Inventory KPI

Inventory Turnover Graph

Understanding Inventory KPIs

1. Why Bother with Inventory KPIs?

Let's be honest, dealing with inventory can feel like herding cats. You've got stuff coming in, stuff going out, and somehow, it never quite matches what you think you should have. That's where Inventory Key Performance Indicators (KPIs) swoop in to save the day! They give you concrete, measurable insights into how efficiently you're managing your stock. Think of them as your inventory superheroes, ready to point out the villains (like excessive carrying costs or stockouts) lurking in the shadows. They provide a roadmap to improve efficiency, reduce costs, and boost customer satisfaction — all without having to resort to spreadsheets that make your eyes cross.

Instead of blindly guessing, you'll have data-driven answers to questions like, "Are we holding too much inventory?" or "Are we consistently running out of that one super popular item?" This allows you to make informed decisions about purchasing, warehousing, and even marketing strategies. And who doesn't want to make smarter decisions based on real evidence?

Essentially, mastering inventory KPIs transforms your supply chain from a potential liability into a competitive advantage. Properly managed inventory means happier customers receiving their orders on time, reduced waste from obsolete stock, and a healthier bottom line overall. It's a win-win-win situation!

So, buckle up as we delve into the exciting world of calculating these crucial metrics! Think of it as leveling up your business skills — each KPI you master unlocks a new ability to optimize your operations and achieve greater success. Consider it a journey into the heart of your business's operational efficiency, where data illuminates the path to smarter decisions and greater profitability.

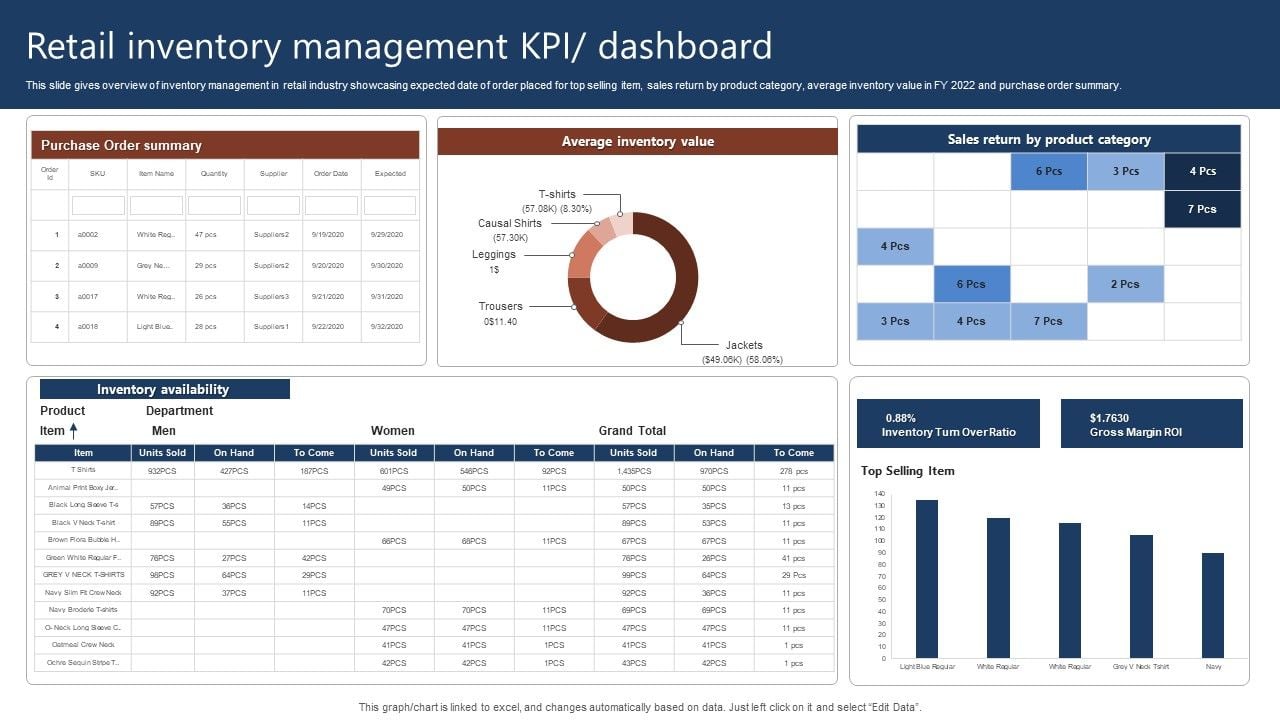

Retail Inventory Management Kpi Dashboard Rules PDF

Calculating the Big Ones

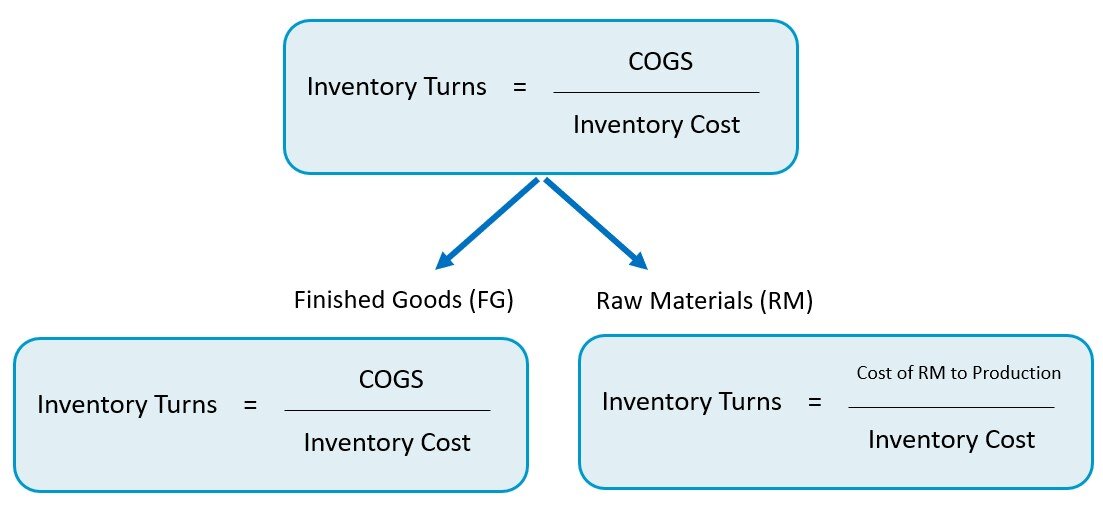

2. Inventory Turnover Ratio

The Inventory Turnover Ratio is like the heartbeat of your inventory management system. It tells you how many times you've sold and replenished your entire inventory over a specific period (usually a year). A higher turnover rate generally suggests efficient sales and minimal holding costs, which is music to any business owner's ears. However, a too high turnover might signal that you're frequently running out of stock, potentially frustrating customers and losing sales. It's a balancing act!

Here's the formula: Inventory Turnover Ratio = Cost of Goods Sold (COGS) / Average Inventory. COGS is the total cost of producing or acquiring the goods you sold during the period. Average Inventory is the average value of your inventory over that same period. You can calculate it by adding your beginning inventory and ending inventory, then dividing by two. Don't worry; you likely already have these numbers in your accounting system!

For example, if your COGS for the year was $500,000 and your average inventory was $100,000, your Inventory Turnover Ratio would be 5. This means you sold and replenished your entire inventory five times during the year. What's considered a "good" ratio varies by industry, so do a little research to see how you stack up against your competitors. Are they managing their inventory more efficiently? What are the average inventory turnover rates of businesses similar to yours?

Think of it like this: A bakery with a turnover ratio of 20 is probably doing better than a car dealership with a turnover ratio of 2. The bakery's goods are perishable, while the cars are not. Analyze your turnover ratio within the context of your industry to gain a deeper understanding of its significance.

3. Days Sales of Inventory (DSI)

Days Sales of Inventory (DSI) tells you, on average, how many days it takes to sell your entire inventory. It's basically the flip side of the Inventory Turnover Ratio coin. A lower DSI is generally better because it means you're turning your inventory into cash faster. The shorter the time your inventory sits on the shelves, the better your liquidity will be.

The formula is: DSI = (Average Inventory / Cost of Goods Sold) x 365. Using the same numbers from our previous example (Average Inventory = $100,000, COGS = $500,000), DSI would be ($100,000 / $500,000) x 365 = 73 days. This means it takes, on average, 73 days to sell your entire inventory. Understanding this metric lets you fine-tune your inventory management to optimize it for speed. Perhaps you can introduce new sales strategies to improve it.

DSI is super helpful for cash flow forecasting. Knowing how long your cash is tied up in inventory allows you to better plan for upcoming expenses and investments. It's like having a crystal ball that shows you how much money you'll have available in the future (at least based on your inventory performance!).

Again, compare your DSI to industry benchmarks. A high DSI could indicate slow-moving inventory, overstocking, or even obsolete products. Time to take a closer look at what's gathering dust in the warehouse!

4. Fill Rate

The Fill Rate measures the percentage of customer orders that you can fulfill immediately from available stock. It's a direct reflection of your ability to meet customer demand and keep them happy. High fill rates generally lead to increased customer loyalty and repeat business, and who doesn't want that?

Calculating fill rate involves dividing the number of orders fulfilled completely and on time by the total number of orders received over a certain period. Its expressed as a percentage. So the formula is: Fill Rate = (Number of Orders Fulfilled Completely and On Time / Total Number of Orders) x 100. If you fulfilled 95 out of 100 orders, your fill rate would be 95%.

A low fill rate might suggest stockouts, poor inventory forecasting, or unreliable suppliers. Its a loud siren indicating that urgent attention is needed. Think of it this way: Every unfilled order is a potential customer heading to your competitor. Ouch!

Improving your fill rate often involves implementing better inventory forecasting techniques, optimizing your reorder points, and building stronger relationships with your suppliers. Sometimes, it might even require investing in additional warehouse space. Regardless, keeping an eye on fill rate helps ensure a seamless customer experience.

Inventory Turnover Ratio Formula

Beyond the Basics

5. Stockout Rate

The Stockout Rate measures how often you run out of a particular item. Running out of popular items can lead to frustrated customers and lost sales, so tracking this KPI is crucial. Nobody likes to hear "Sorry, we're out of that right now."

The formula is: Stockout Rate = (Number of Times an Item is Out of Stock / Total Number of Times That Item is Requested) x 100. Let's say you ran out of your best-selling widget 5 times out of 100 requests. Your stockout rate would be 5%.

Analyzing stockout rates helps identify items that consistently need better inventory management. You might need to increase your safety stock levels for these items or improve your demand forecasting accuracy. It's all about understanding which products are most vulnerable to stockouts and taking proactive steps to prevent them.

Think of it as playing detective: A high stockout rate is a clue that something's amiss in your supply chain. It's your job to investigate and find the root cause of the problem.

6. Holding Cost

Holding Cost, also known as carrying cost, represents the total expenses associated with storing and maintaining your inventory. This includes things like warehouse rent, utilities, insurance, and even the cost of obsolescence. Ignoring holding costs can seriously eat into your profits.

Calculating holding cost requires a bit more effort, as it involves adding up all the relevant expenses. The formula is: Holding Cost = (Storage Costs + Capital Costs + Risk Costs) / Average Inventory Value. Storage costs include rent, utilities, and warehouse personnel expenses. Capital costs represent the opportunity cost of tying up capital in inventory (i.e., what you could have earned if you invested that money elsewhere). Risk costs include insurance, obsolescence, and spoilage.

Understanding your holding costs helps you make informed decisions about inventory levels. If your holding costs are too high, you might need to reduce your inventory levels or find ways to improve your warehouse efficiency. Think of it as trimming the fat from your operations — eliminating unnecessary expenses to boost your bottom line. Also, look into faster inventory management system or better tracking system.

Remember, holding costs are not just about the money you're spending; they're also about the opportunities you're missing. Minimizing these costs frees up capital for other investments that can help your business grow.

Top 30 KPIs For Inventory Managers

Putting It All Together

7. Analyzing the Data

Calculating inventory KPIs is only half the battle. The real magic happens when you start analyzing the data and using it to make informed decisions. Look for trends, patterns, and outliers that can provide insights into your inventory management performance. Don't just calculate the numbers; understand what they mean.

For example, if you notice that your inventory turnover ratio has been steadily declining over the past few months, it might indicate that you're holding too much inventory or that your sales are slowing down. Similarly, a consistently high stockout rate for a particular item might suggest that you need to increase your order frequency or find a more reliable supplier. It's the "why" behind the numbers that unlocks the real value of KPIs.

Think of your inventory KPIs as pieces of a puzzle. Each KPI provides a different perspective on your inventory management performance. By putting all the pieces together, you can get a clear picture of what's working well and what needs improvement. Don't be afraid to experiment and try new strategies to optimize your inventory levels.

Share the data! Make sure your team is aware of the KPIs and how they're being used to make decisions. Transparency fosters a culture of continuous improvement.

8. Taking Action

Once you've analyzed your inventory KPIs, it's time to take action. Develop a plan to address any identified weaknesses and capitalize on your strengths. Don't just sit on the data; use it to drive meaningful change. Create a project with a specific goal and stick with it.

For example, if your fill rate is low, you might need to implement better inventory forecasting techniques, optimize your reorder points, or build stronger relationships with your suppliers. If your holding costs are too high, you might need to reduce your inventory levels or find ways to improve your warehouse efficiency. The key is to identify the root causes of the problems and develop targeted solutions.

Remember, improving inventory management is an ongoing process. Regularly monitor your KPIs and adjust your strategies as needed. Think of it as fine-tuning a musical instrument — constantly making small adjustments to achieve optimal performance. A successful inventory management system is about continuous improvement.

And dont be afraid to ask for help! Consult with industry experts or use inventory management software to streamline your processes and gain deeper insights into your data. Sometimes a fresh perspective is all you need to unlock new opportunities.

FAQ

9. Q

A: There's no single "most important" KPI. It depends on your specific business goals and industry. However, Inventory Turnover Ratio, Days Sales of Inventory (DSI), and Fill Rate are generally considered essential for most businesses. Pick the right tools for the job.

10. Q

A: It depends on the KPI and your business needs. Some KPIs, like Fill Rate, might need to be tracked daily or weekly, while others, like Inventory Turnover Ratio, can be calculated monthly or quarterly. Regularly monitor KPIs to keep inventory optimized.

11. Q

A: Don't panic! It's important to understand why your KPIs are different. It could be due to unique business strategies, market conditions, or even data errors. Investigate the reasons behind the variance and take appropriate action. Research why your KPIs are different and adjust.