Beautiful Tips About How To Do Crimping Without Crimper

Crimping Cables Without a Crimper

1. When Your Crimper Goes AWOL

Alright, let's face it. We've all been there. You're knee-deep in a wiring project, finally about to connect that crucial cable, and...bam! Your trusty crimper is nowhere to be found. Maybe it's hiding in the abyss of your toolbox, maybe your neighbor "borrowed" it and forgot to return it (again!), or maybe it decided to take an early retirement. Whatever the reason, you're stranded. But don't despair! There are ways to achieve a solid connection without that dedicated tool. It might not be the ideal solution, but in a pinch, it can definitely save the day. We're talking MacGyver-level stuff here, so buckle up!

Before we dive in, let's be clear: How to do crimping without crimper comes with risks. A properly crimped connection is essential for reliable data transfer and preventing shorts or fires. These methods are primarily for temporary fixes or low-stakes situations. If you're dealing with critical network infrastructure or high-voltage applications, seriously consider waiting and getting your crimper back, or investing in a new one. Safety first, always!

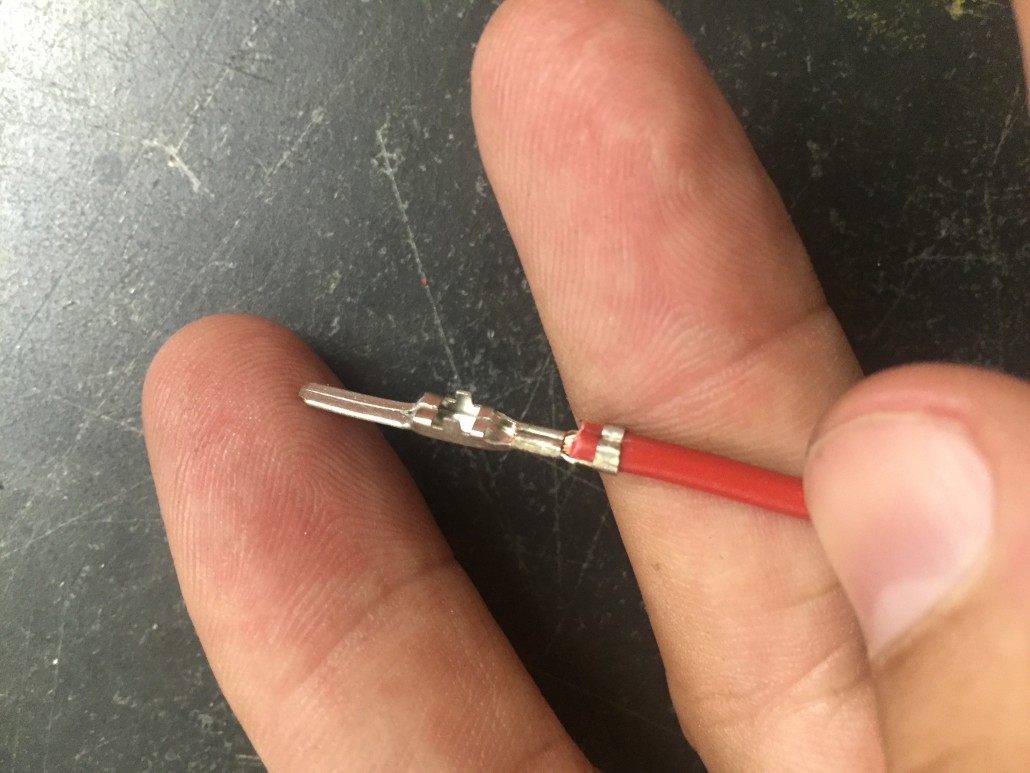

The key to success here is understanding what a crimper actually does. It essentially squeezes the connector's metal contacts around the individual wires, creating a gas-tight seal that ensures a secure electrical connection and physical grip. Our mission is to mimic that pressure and create a similar result. It requires some patience, a steady hand, and a healthy dose of "winging it."

Think of it like this: youre essentially performing delicate surgery on a tiny metal connector. Precision is key. A slip-up could mean a dodgy connection or, worse, a damaged cable. So, take a deep breath, clear your workspace, and let's get to work. Remember, were aiming for functional, not perfect. But functional is often good enough to get you back online!

The Toolbox of Last Resort

2. Your New Best Friends (Until You Find Your Crimper)

So, what can you use in place of a crimper? The answer depends on what you have lying around. Here are a few common household and workshop tools that can be pressed into service:

First, the needle-nose pliers. These are your primary weapon. The pointed tips allow you to focus pressure on specific areas of the connector. You'll use them to gently bend and squeeze the metal tabs that hold the wires in place.

Next, a small flat-head screwdriver. This will be your precision instrument. Use it to carefully push wires into their slots within the connector and to further refine the crimped connection after the pliers have done their initial work. Think of it as sculpting, but with wires and metal.

Third, a wire stripper (or, in a pinch, a sharp knife). This is crucial for preparing the wires before insertion. A clean strip is essential for a good connection. If using a knife, be extremely careful not to nick or cut the copper strands. Were aiming for precision, not a blood sacrifice.

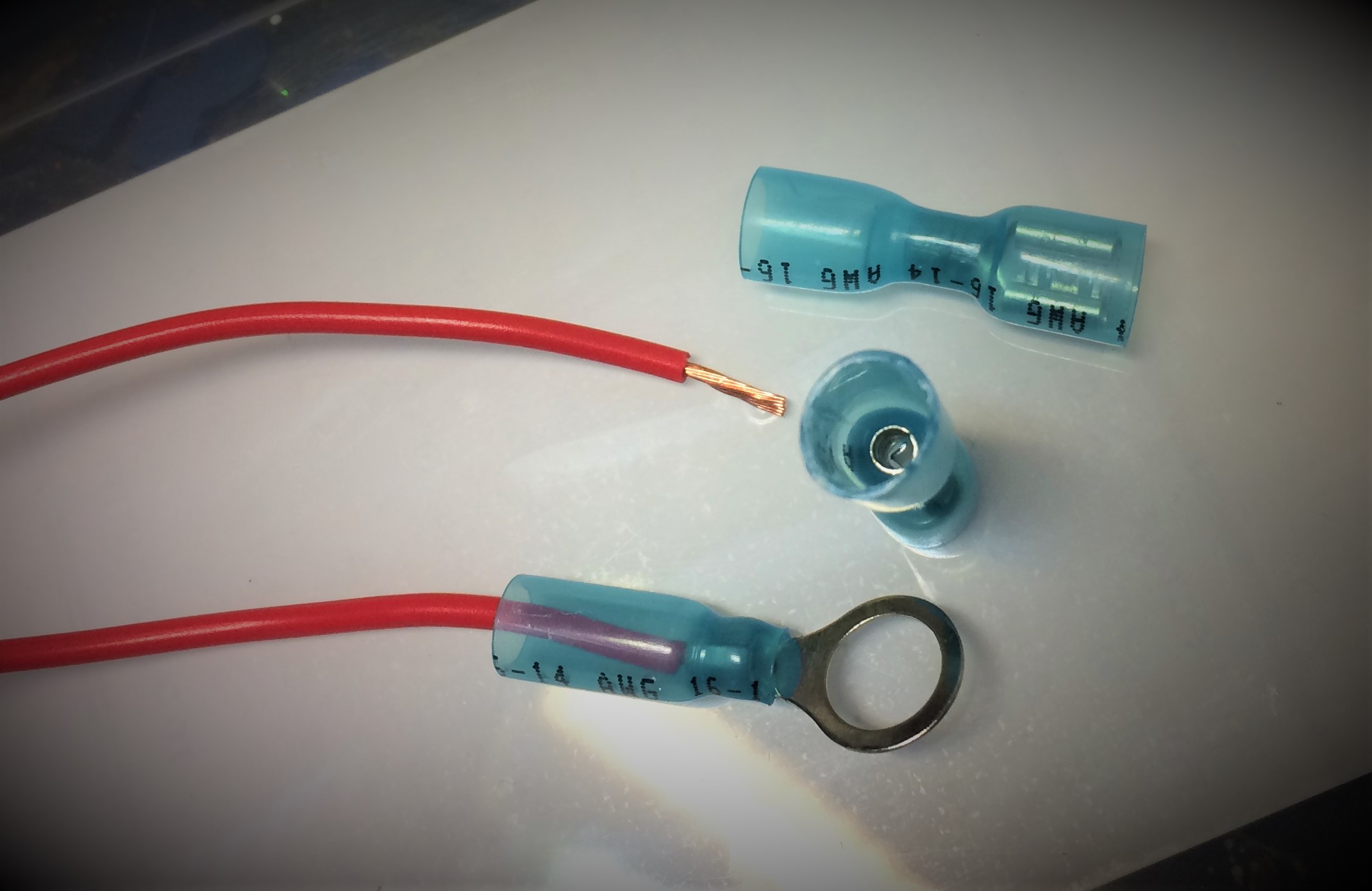

Finally, electrical tape. This is your safety net. Once the connection is made, wrap the connector securely with electrical tape to provide insulation and prevent accidental shorts. Think of it as insurance against Murphy's Law. Remember: Electrical tape is not a substitute for a properly crimped connection, but it can offer an extra layer of protection.

How Crimp Hair Without A Crimper At Anton Thomas Blog

The Crimping Process

3. Let's Get Those Wires Connected!

Okay, gather your tools and your connector. Let's walk through the how to do crimping without crimper process. Remember, patience is a virtue, especially when you're improvising.

Start by preparing your wires. Use your wire stripper (or carefully, carefully using your knife) to remove about half an inch of insulation from the end of each wire. Make sure you don't cut any of the strands. If you do, trim them back and start again. A frayed wire is a bad wire.

Next, carefully insert each wire into its corresponding slot in the connector. Refer to the wiring diagram for your specific cable type (e.g., T568A or T568B for Ethernet cables). Ensuring the correct order is paramount. Incorrect wiring will render your cable useless, or worse, cause network issues.

Now comes the tricky part. Using your needle-nose pliers, gently squeeze the metal tabs on the connector down onto the insulated part of the wire. This is the first line of defense. Apply even pressure to each tab. Don't over-squeeze, as you could damage the connector. Aim for a firm but not crushing grip.

Finally, using your small flat-head screwdriver, carefully push the metal teeth (or prongs) of the connector into the copper strands of the wire. This is where you're trying to replicate the gas-tight seal that a crimper creates. Be precise and deliberate. Check the connection visually to ensure that each wire is securely held in place.

Testing and Securing Your Improvised Connection

4. Don't Celebrate Just Yet!

Alright, you've (hopefully) managed to crimp the connector without a crimper. But don't start celebrating just yet. The real test is whether the connection actually works. And, crucially, whether it's safe.

First, give the wires a gentle tug. If any wires come loose, the connection is not secure enough. You'll need to go back and re-crimp, paying closer attention to the metal tabs and prongs. A loose connection is a recipe for disaster.

Next, if you're working with a data cable (like Ethernet), test the connection using a cable tester. This will verify that all the wires are properly connected and that there are no shorts or opens. A cable tester is an invaluable tool for troubleshooting network issues. If the cable fails the test, you'll need to re-crimp, paying close attention to the wiring order and the quality of the connection.

Finally, once you're satisfied that the connection is secure and functioning correctly, wrap the connector with electrical tape. This will provide insulation and prevent accidental shorts. Overlap the tape to ensure a complete seal. Remember, electrical tape is not a substitute for a proper crimp, but it does provide an extra layer of protection.

Keep in mind that connections made without a crimper are more likely to fail over time. Regularly inspect the connection for signs of corrosion or looseness. If you notice any problems, replace the connector with a properly crimped one as soon as possible.

How To Crimp Short Hair Without A Crimper At Michael Gates Blog

When to Admit Defeat (and Buy a New Crimper)

5. Knowing When to Throw in the Towel

Let's be real. While these methods can work in a pinch, they're not a substitute for a proper crimper. There are situations where attempting to crimp without the right tool is simply not worth the risk or the hassle. Knowing when to admit defeat is a sign of wisdom, not weakness.

If you're working with high-voltage applications, don't even think about it. Messing around with electricity without the proper tools and safety precautions is incredibly dangerous. Leave it to the professionals. Your life is worth more than saving a few bucks on a crimper.

If you're making a critical network connection (like the backbone of your office network), it's also best to use a crimper. Downtime can be costly, and a flaky connection can cause all sorts of problems. Invest in a good quality crimper and do the job right the first time.

And finally, if you've tried multiple times and still can't get a secure connection, it's time to throw in the towel. Sometimes, the connector is simply too damaged, or your technique isn't quite up to par. Don't waste your time and energy on a lost cause. Go buy a new crimper (or borrow one from a friend) and get the job done properly. Your sanity (and your network) will thank you.

FAQ

6. Frequently Asked Questions About Crimper-less Connections

Got some burning questions about how to do crimping without crimper? Here are a few common concerns:

7. Q

A: "Safe" is a relative term. It's safer to use a crimper. These methods are for emergencies only. Low-voltage, temporary fixes are the name of the game. Always prioritize safety and use electrical tape generously.

8. Q

A: Nope. A properly crimped connection is designed to last for years. An improvised connection is more likely to fail over time due to corrosion, vibration, or simple wear and tear. Regularly inspect and replace as needed.

9. Q

A: Generally, these techniques are best suited for smaller connectors like RJ45 (Ethernet) or RJ11 (telephone). Larger or more complex connectors may require specialized tools. Trying to MacGyver a coaxial cable connection is probably not a good idea.