Divine Info About Should Continuity Read 0

Should Continuity Really Be Zero? Let's Unpack This.

1. What Does "Continuity Read 0" Even Mean?

Okay, so you've stumbled across the phrase "continuity read 0." It sounds rather technical, doesn't it? Like something out of a sci-fi movie. In the electrical world, "continuity" essentially means if a circuit is complete — think of it like a perfectly paved road for electricity to travel. When a meter reads "0" for continuity, it's saying, "Yep, the road is open! Traffic (electricity) can flow freely." But the real question is, should that always be the case?

Imagine you're checking the wiring in your old lamp. You expect the wires to be connected, right? A reading of zero would be good news there! It means the path is clear. However, what if you were checking the continuity between two separate wires? A zero reading there would scream "Short circuit!" and that's definitely not good. So, context is everything. Saying continuity read 0 is perfect, really depends on what are you testing with continuity zero.

Consider it like this: you expect the water pipes leading to your faucet to be connected (continuity read 0 is good). But you definitely don't want the water pipes connected directly to the gas line. (Continuity read 0 is very, very bad!). See how a seemingly simple measurement can have wildly different implications?

So, instead of blindly accepting "continuity read 0" as universally desirable, let's dig a little deeper into when it's a thumbs-up and when it's a red flag. After all, knowing the difference could save you a blown fuse — or worse! The value of zero really depends on what you expect in a certain situation. If zero is not an expected value, then it is an indicator of something that is wrong.

Testing Continuity With A Multimeter Chibitronics

The Good, the Bad, and the Zero

2. When Zero is a Hero

Let's start with the feel-good moments, the times when "continuity read 0" makes you want to do a little jig. Think about checking a fuse. A blown fuse means an open circuit, and your appliance is dead. A healthy fuse should have a resistance close to zero, indicating a complete path for electricity. You are hoping to get a value of zero to ensure things are as it should be.

Another example: wiring inside an electrical cord. You want those wires to be perfectly connected from plug to appliance. A near-zero reading confirms that the electricity has a smooth, uninterrupted path. This is critical for the safe operation of anything from your toaster to your TV. So, when you're verifying simple connections, "continuity read 0" is your best friend and indicates a good working order.

Also, when you are tracing some wires, you expect it to read zero, so you can confirm you have the right wire, this could be inside of a wall, or in a bundle of cables inside of a control panel. Knowing that the cable is zero, lets you mark it so you know what it is later.

However, remember even in these seemingly straightforward situations, double-checking is always a good idea. Make sure you're testing the correct points. Mistaking two wires for each other could lead to a misdiagnosis, and that's never fun. Trust me, I've been there, done that, got the slightly singed T-shirt. So measure twice, cut once, or in our case, measure twice, troubleshoot once.

SPARK PLUG CONTINUITY TEST How To Check The Continuity Of Spark Plugs

When Zero Spells Trouble

3. The Dark Side of Zero

Now, let's venture into the shadowy realm where "continuity read 0" sends shivers down your spine. This is when you're checking for shorts or ground faults. A short circuit happens when electricity finds an unintended, low-resistance path back to the source, bypassing the intended load. This can cause excessive current flow, overheating, and potentially, a fire. Not good!

Imagine, for instance, that you're testing the continuity between the metal chassis of an appliance and a live wire. A healthy appliance should have no connection between them. A reading of zero would indicate that the insulation has failed, and the chassis is now energized. Touching that appliance could give you a nasty shock. That reading would not be a good value.

Similarly, if you are working on a car and the continuity between the frame of the car and the battery positive is zero, that means something is seriously wrong. This usually means some sort of insulation is broken somewhere, and the electrical power is going straight to ground, or the metal frame of the car. This could cause a fire or even damage to components in the car.

So, when troubleshooting, understanding the expected resistance between different points is critical. "Continuity read 0" can be a silent alarm, warning you of a potentially dangerous situation. Ignoring it is like ignoring the flashing lights on a faulty smoke detector. Pay attention! Safety first, always.

How To Perform A Continuity Test For Electrical Components With

Tools of the Trade

4. Getting Hands-On with Continuity Checks

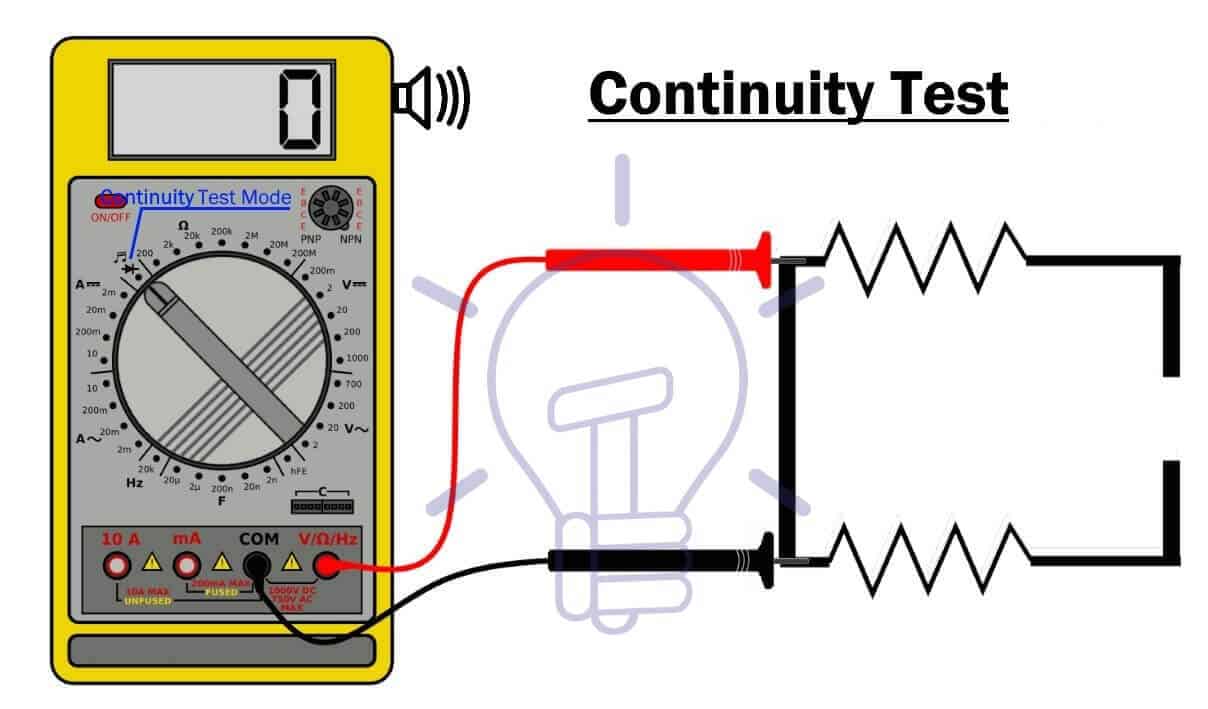

So, how do we actually perform these continuity tests? The star of the show is the multimeter. This versatile tool can measure voltage, current, and — you guessed it — resistance (which is how we determine continuity). Most multimeters have a dedicated continuity setting, often indicated by a diode symbol or a sound wave symbol. When continuity is detected (low resistance), the meter will beep, giving you an audible confirmation.

Before you even think about sticking those probes anywhere, make sure the circuit you're testing is de-energized. I repeat: de-energized! Turn off the power, unplug the appliance, remove the battery — whatever it takes to make sure no electricity is flowing. Testing a live circuit for continuity is a recipe for disaster (and potentially a very shocking experience).

Next, select the continuity setting on your multimeter. Touch the two probes together. The meter should beep and display a reading close to zero. This confirms that the meter is working correctly. If it doesn't beep, check the battery or the fuse inside the meter. Then, place the probes across the points you want to test. If the meter beeps and displays a low resistance, you have continuity. If it doesn't, you don't. Simple as that!

Also, some multimeters have the ability to hold and record maximum and minimum values. When doing continuity tests, this is a good tool to use, that way you have a record of the values. This will help you to make a log of all your tests.

How To Test Cord Multimeter At Benjamin Downie Blog

Beyond the Basics

5. Diving Deeper into the World of Resistance

While "continuity read 0" is often the goal, it's important to remember that nothing is perfectly zero in the real world. Even a solid wire has some resistance, albeit very small. A reading of 0.1 ohms is usually considered good continuity, especially in low-voltage circuits. However, in sensitive electronic circuits, even a fraction of an ohm can make a difference.

Consider the length of the wire. A long wire will have more resistance than a short wire of the same gauge. The material of the wire also matters. Copper is a better conductor than steel, so it will have lower resistance. Also, the quality of the connection matters. A corroded or loose connection will have higher resistance than a clean, tight connection.

Furthermore, some circuits are designed to have a certain amount of resistance. For example, a heating element in a toaster is designed to resist the flow of electricity, generating heat as a result. Testing the continuity of a heating element should give you a reading above zero, indicating that the element is intact and functioning correctly. If it reads zero, the element is shorted and needs to be replaced.

In the end, understanding continuity isn't just about getting a "0" reading. It's about understanding what that reading means in the context of the specific circuit you're testing. So, arm yourself with knowledge, a good multimeter, and a healthy dose of common sense, and you'll be well on your way to mastering the art of continuity testing.

FAQ

6. Your Burning Questions Answered

Let's tackle some of those nagging questions you might have about continuity and what a "0" reading really means.

Q: My meter reads "OL" instead of a number. What does that mean?

A: "OL" stands for "Overload" or "Open Loop." It means the resistance is too high for the meter to measure. Basically, there's no continuity.

Q: Can I test continuity on a live circuit if I'm really careful?

A: NO! Just kidding... kind of. Seriously, never test continuity on a live circuit. It's dangerous and can damage your meter. Always de-energize the circuit first.

Q: I get a "0" reading when I don't expect it. What should I do?

A: First, double-check your connections and make sure you're testing the correct points. Then, look for potential short circuits, such as frayed wires or loose connections. If you're not comfortable troubleshooting yourself, consult a qualified electrician. It's better to be safe than sorry!

Q: What is the best tool for the job?

A: A multi-meter will usually be the best tool, but you can also use a tool called a continuity tester. A continuity tester is basically a multi-meter that is designed just to do one thing, that is to test continuity.