Sensational Info About What Color Wires Are 3 Phase

Color Code For 3 Phase Wire

Decoding the Rainbow

1. Why Color Matters in Electrical Systems

Ever wondered why electrical wires aren't just all the same color? It's not just for aesthetics, trust me! Color coding in electrical systems, especially when dealing with 3 phase power, is absolutely crucial for safety and proper functioning. Imagine trying to rewire something without knowing which wire goes where — sounds like a recipe for disaster, right? It's like trying to assemble IKEA furniture without the instructions!

The main reason for color-coding is to easily identify the different conductors (wires) in the circuit. This helps electricians quickly determine the purpose of each wire, reducing the risk of electrical shock, short circuits, and equipment damage. In a 3 phase system, this is even more vital because you're dealing with higher voltages and more complex configurations.

Think of it like traffic lights: red means stop, yellow means caution, and green means go. If those weren't standardized, driving would be chaotic! Similarly, standardized wire colors prevent electrical mayhem.

The color coding isn't just some random suggestion; it's actually dictated by electrical codes like the National Electrical Code (NEC) in the United States and the International Electrotechnical Commission (IEC) standards used globally. These codes ensure consistency and safety across different installations, making it easier for electricians to work on various projects, regardless of where they are.

North American Standards

2. Unraveling the NEC Wire Color Code

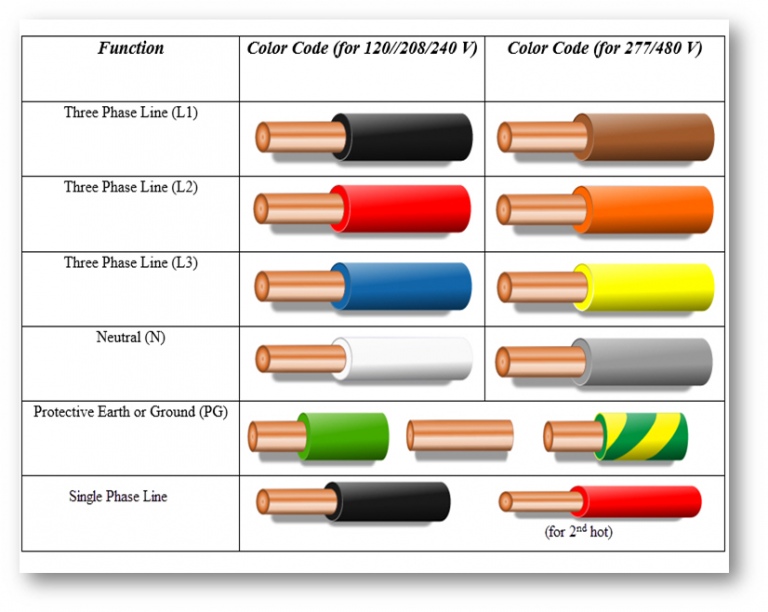

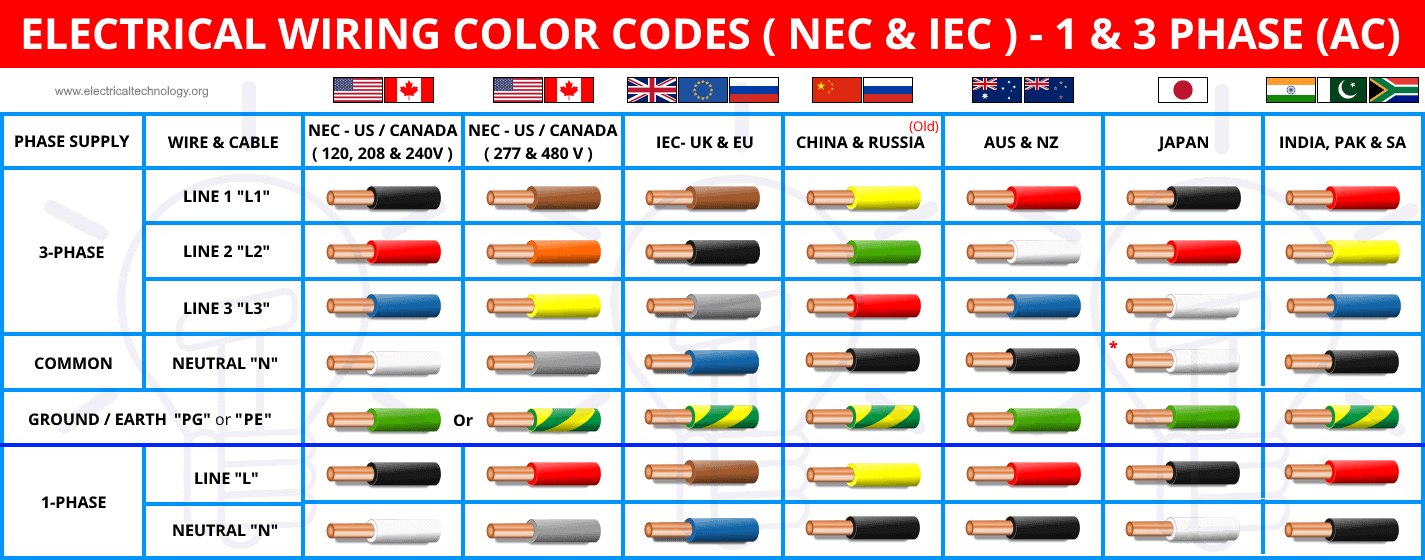

Okay, let's dive into the colors used in North America, primarily governed by the NEC. Its like learning a secret language, but instead of impressing your friends, youre preventing electrocution! For a 3 phase system operating at 480V, you'll typically see these colors:

Phase A is usually Brown. Phase B is Orange. Phase C is Yellow. And neutral is typically Gray or White. Ground, or earth, is always Green (or sometimes bare copper). Now, why these specific colors? Well, they provide good contrast and visibility, making them easy to distinguish, even in dimly lit electrical panels. Its all about safety and quick identification.

It's incredibly important to note that older installations might use different color schemes. So, always verify the wiring configuration before working on any electrical system, no matter how confident you are. A simple voltage test can save you from a shocking experience! Always treat every wire as if it is live until you have personally confirmed it is not.

Also, the NEC allows for re-identification of wires in certain circumstances using colored tape or marking. For example, if you're using a wire color that isn't the standard for a specific purpose, you can wrap it with the appropriate colored tape at each termination point to clearly indicate its function. Think of it as giving the wire a name tag!

Electrical Wire Color Code 3 Phase

International Standards

3. IEC Wire Color Codes Explained

Across the pond, or really, in most places not North America, the IEC standards reign supreme. The color coding is a bit different, but the goal is the same: safety and clarity. It's like driving on the left side of the road — you just need to know the rules! For 3 phase systems, the IEC generally uses the following:

Phase L1 is Brown. Phase L2 is Black. Phase L3 is Grey. The neutral conductor is Blue, and the protective earth (ground) is Green with Yellow stripe. Notice the slight variations from the NEC? Thats why its vital to know which standard applies to the system you're working on.

Again, just like with the NEC, older installations might have different color codes. So, always, always verify the wiring configuration. Don't assume anything based on color alone. Electricity is unforgiving!

The IEC also allows for re-identification of wires, similar to the NEC. If a wire doesn't have the standard color, it can be marked with the appropriate color tape or sleeves. This ensures that everyone working on the system understands the function of each conductor, regardless of its original color.

Common Electrical Wire Colors

Why Uniformity Matters

4. The Importance of Consistent Color Coding

Imagine a world where stop signs were sometimes green and sometimes purple. Chaos, right? That's why uniformity in electrical wiring is so important. When everyone follows the same color code, it eliminates confusion and reduces the risk of errors. It's like having a universal language for electricians.

Consistent color coding significantly improves safety. Electricians can quickly identify the different conductors, reducing the chance of accidental contact with live wires. This is especially crucial in emergency situations where time is of the essence. Clear and consistent markings can save lives.

It also makes troubleshooting and maintenance much easier. When a problem arises, electricians can quickly trace the circuit and identify the faulty component without having to guess which wire is which. This saves time and money, and minimizes downtime.

Furthermore, adherence to standardized color codes ensures compliance with safety regulations and electrical codes. This not only protects workers and property but also reduces liability for employers and building owners. Its a win-win for everyone involved.

Beyond the Basics

5. Tips and Tricks for Working with 3 Phase Systems

While understanding the basic color codes is essential, there are a few other things to keep in mind when working with 3 phase systems. First off, always double-check the voltage of the system before you start working on it. Using the wrong tools or procedures can be extremely dangerous. Think of it as using the right ingredients for a recipe — you can't make a cake with motor oil!

Secondly, remember that color codes can vary depending on the specific application and the region. Always consult the relevant electrical codes and standards for the area you're working in. Dont just assume you know the colors based on past experience. A little research can go a long way.

Thirdly, use a reliable voltage tester to verify that the wires are de-energized before touching them. Don't rely on the color code alone. Always treat every wire as if it is live until you have personally confirmed it is not. This is the golden rule of electrical safety.

Finally, if you're not comfortable working with electricity, don't! Hire a qualified electrician. Electricity is nothing to mess with. It's better to be safe than sorry.

Standard Color Coding For 3 Phase Wiring

Frequently Asked Questions (FAQs)

6. Your Burning Questions Answered

Q: What happens if I mix up the wires in a 3 phase system?A: Mixing up the wires can lead to serious problems, including equipment damage, electrical shock, and even fire. The consequences depend on the specific error, but its always best to avoid any mistakes by carefully following the color codes and verifying the wiring before energizing the system.

Q: Can I use any color tape to re-identify wires?A: No, you should only use electrical tape that is specifically designed for wire marking. These tapes are typically color-coded and have adhesive properties that are suitable for electrical applications. Avoid using regular tape or other materials that could degrade over time or cause electrical hazards.

Q: What if I encounter an old wiring system with no color codes?A: If you encounter an old wiring system with no color codes, proceed with extreme caution. Use a voltage tester to identify each conductor and label them clearly. Consult with a qualified electrician if you're unsure about anything. Its better to take extra precautions than to risk an electrical accident.